Plastic Extrusion: How It Works and Why It’s Key in Industrial Projects

1. What is Plastic Extrusion?

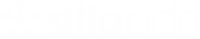

Extrusion is a continuous manufacturing process used to transform thermoplastic materials into constant cross-section profiles or parts. The material is melted and pushed through a die, which shapes it into its final geometry. Once cooled, the piece maintains its mechanical and dimensional integrity. Its versatility makes it one of the most essential techniques in plastic profile extrusion, widely used in industries such as automotive, construction, electrical, and furniture manufacturing.

Nuevo título

2. Our Plastic Extrusion Process Step by Step

In our plastic profile extrusion process, every stage is monitored to ensure precision and stability.

1. Material feeding and melting.

Thermoplastic pellets are fed into a rotating screw inside a heated barrel, where they melt uniformly.

2. Shaping through the die.

The molten material passes through a die designed according to the desired profile geometry and tolerance.

3. Cooling and calibration.

The profile is cooled in a water or air system that solidifies it while maintaining dimensional accuracy.

3. Materials and Process Flexibility

One of the main advantages of plastic extrusion is its ability to adapt to a wide range of materials and specifications.

We work with thermoplastics such as PVC, PE, PP, ABS, and PC—each selected based on the mechanical or environmental requirements of the final product (e.g., resistance, flexibility, rigidity, or clarity).

For projects requiring multiple properties in a single component, we use plastic profile coextrusion, which combines two or more materials during the extrusion process.

This allows us to create profiles with dual functionality—for example, a rigid core with a flexible or colored outer layer—without additional post-processing.

This adaptability makes it possible to develop custom plastic profile extrusion solutions for highly specific industrial applications while maintaining process efficiency.

4. Precision and Quality Control

In plastic profile extrusion companies, process stability defines product quality. Every extrusion line is equipped with temperature and pressure monitoring systems that ensure consistent material flow and uniform melting.

During cooling, dimensional checks are performed continuously to maintain tight tolerances, and parameters are adjusted in real time when necessary.

This level of control reduces deviations, minimizes waste, and extends tooling life.

Regular in-line and post-production inspections ensure that every extruded plastic component meets design and performance expectations before delivery.

5. Why Extrusion Is Key in Industrial Manufacturing

Plastic extrusion offers significant advantages for industrial manufacturing:

- Continuous and efficient production of high volumes.

- Repeatable precision and dimensional consistency.

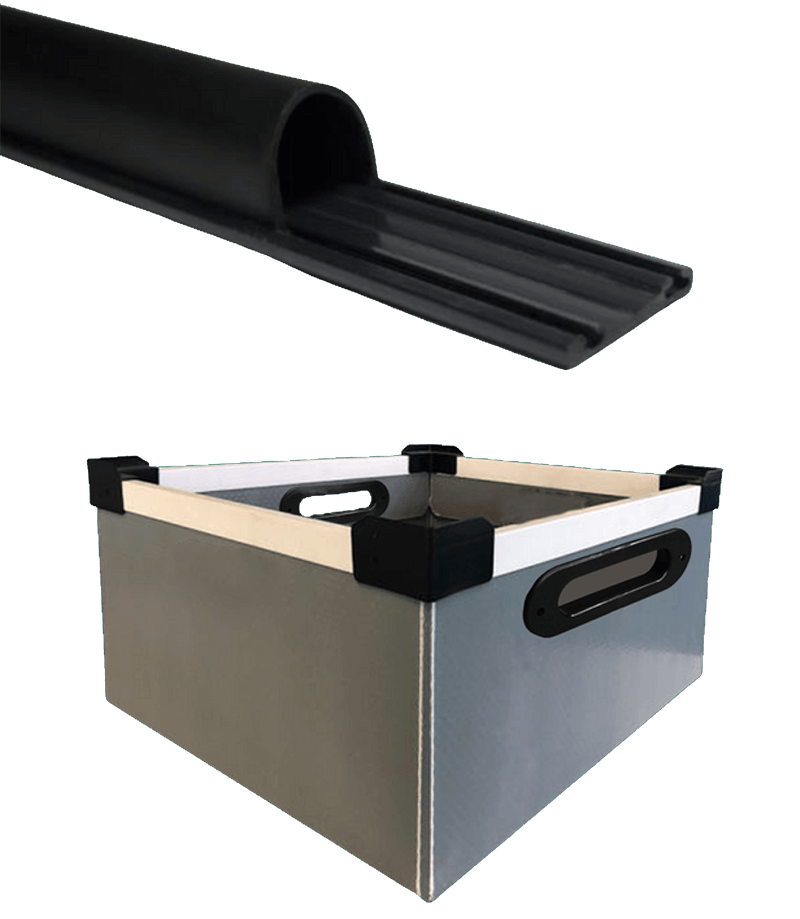

- Flexibility to design custom plastic profiles with complex geometries.

- Reduced material waste and shorter cycle times.

- Compatibility with plastic profile coextrusion for advanced performance.

These characteristics make extrusion an essential process for producing extruded plastic corner profiles, seals, ducts, and technical parts used across different industries.

Our expertise in material selection, process optimization, and tooling development allows us to deliver reliable, high-performance solutions that meet the most demanding industrial standards.